iQ Technology for TOOL and PPE

Any manufacturing environment that has employees and assets would benefit from VendSafety and iQ Technology. It could be manufacturing facilities, warehouses, factories, the list goes on and on.

Take a manufacturing floor with multiple assets and resources critical for productivity, for example. Manufacturers comply with various regulations, rules, and best practices to ensure employee safety and effectiveness. These companies make it work with multiple departments in tow. Our tool and PPE tracking systems help all stakeholders with:

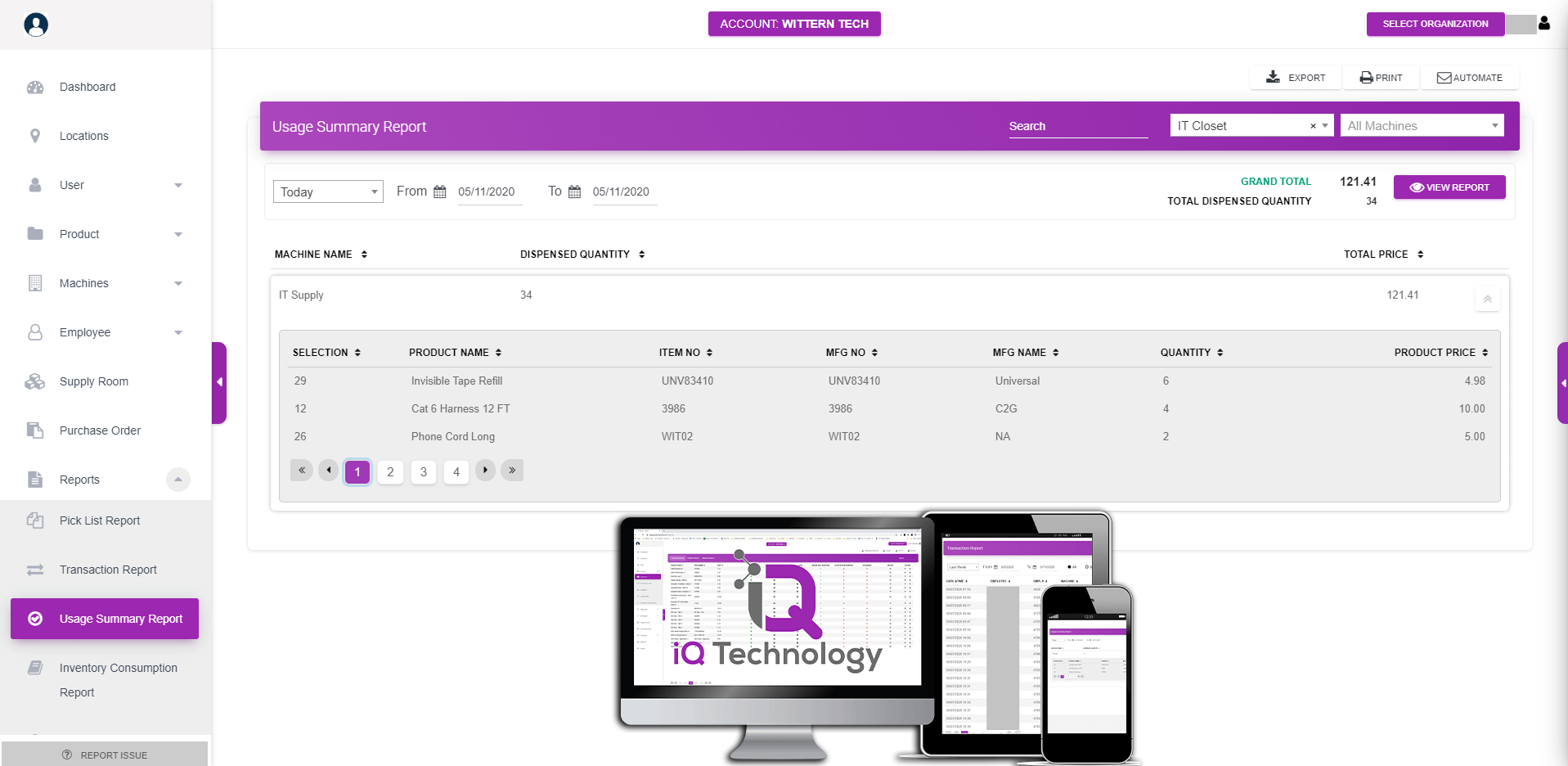

- Real-time and future clarity on resources and their utilization

- An understanding if the desired organizational goals are being met or missed.

- The platform to derive insights to optimize or course-correct

For instance, numerous consumables are required on the floor, ranging from simple gloves and safety goggles to sophisticated tools or machinery. These require controlled access and real-time tracking for safety, security, or effective utilization (in the case of shared resources).

VendSafety and iQ Technology directly benefits

- Manufacturing floors for visibility into resource availability

- Manufacturing operations, in terms of productivity

- Admin and supply chain teams to derive more usable mileage from their budgets

- Management to view the value of their investment

- HR for compliance purposes